Background

General spec inluded

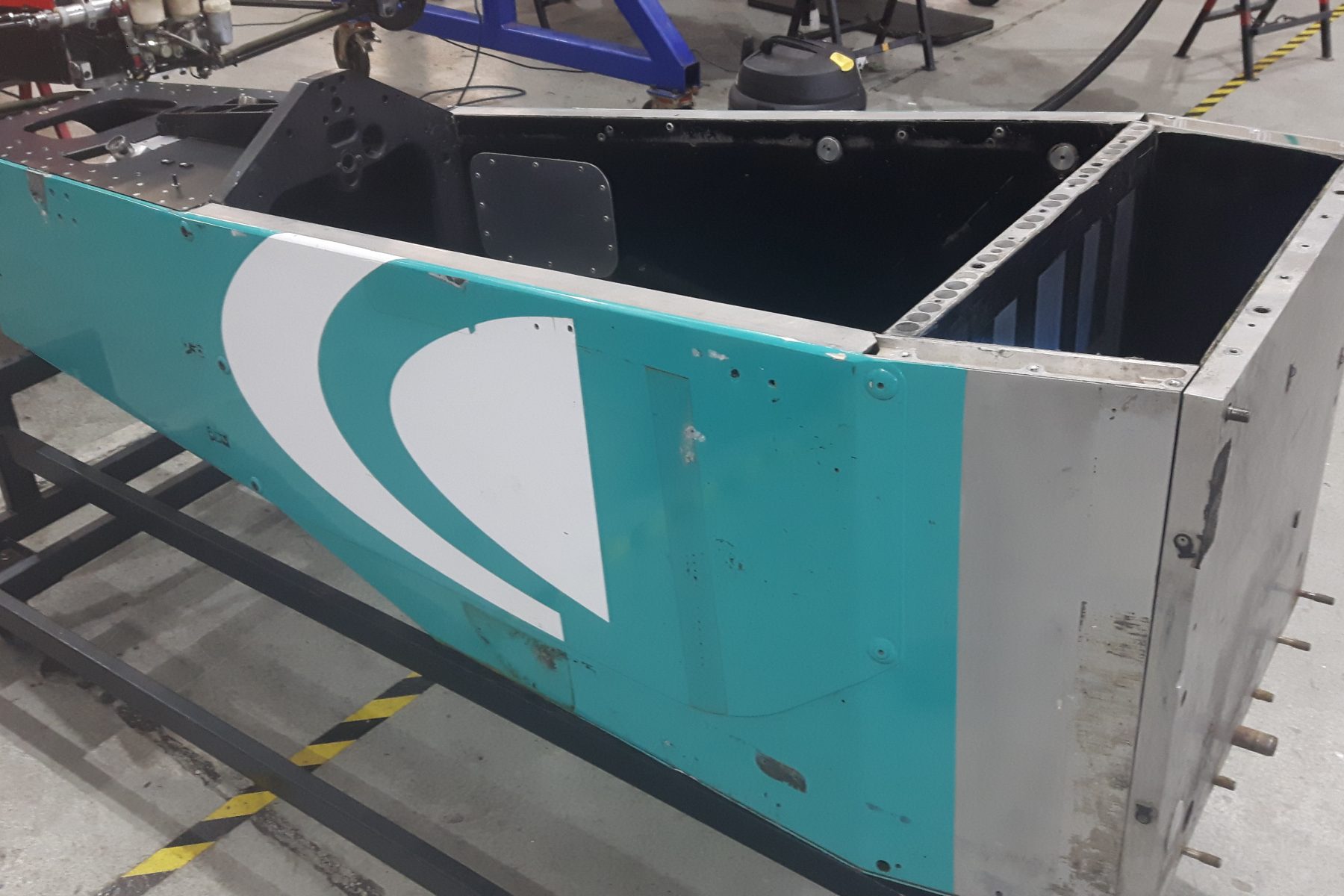

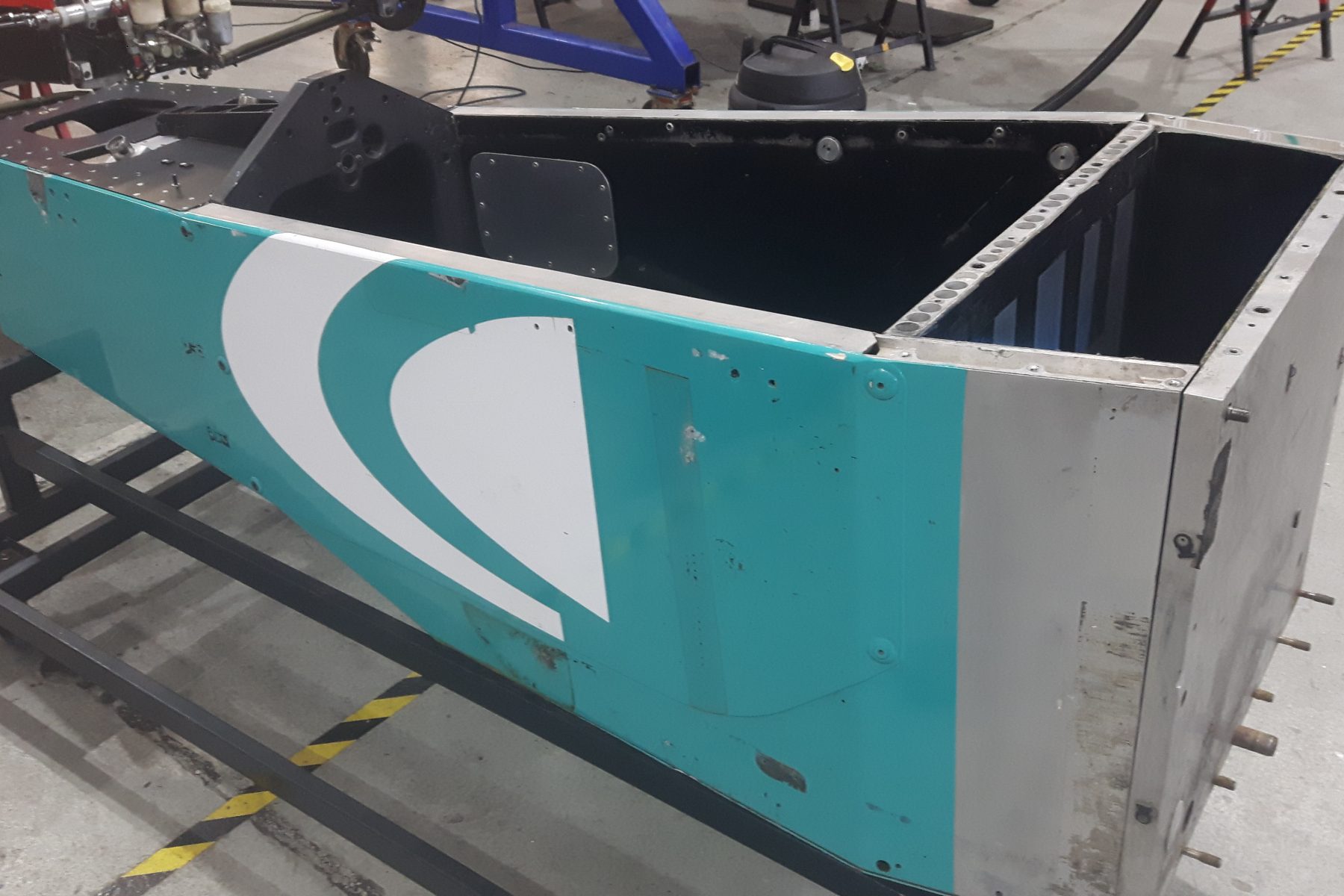

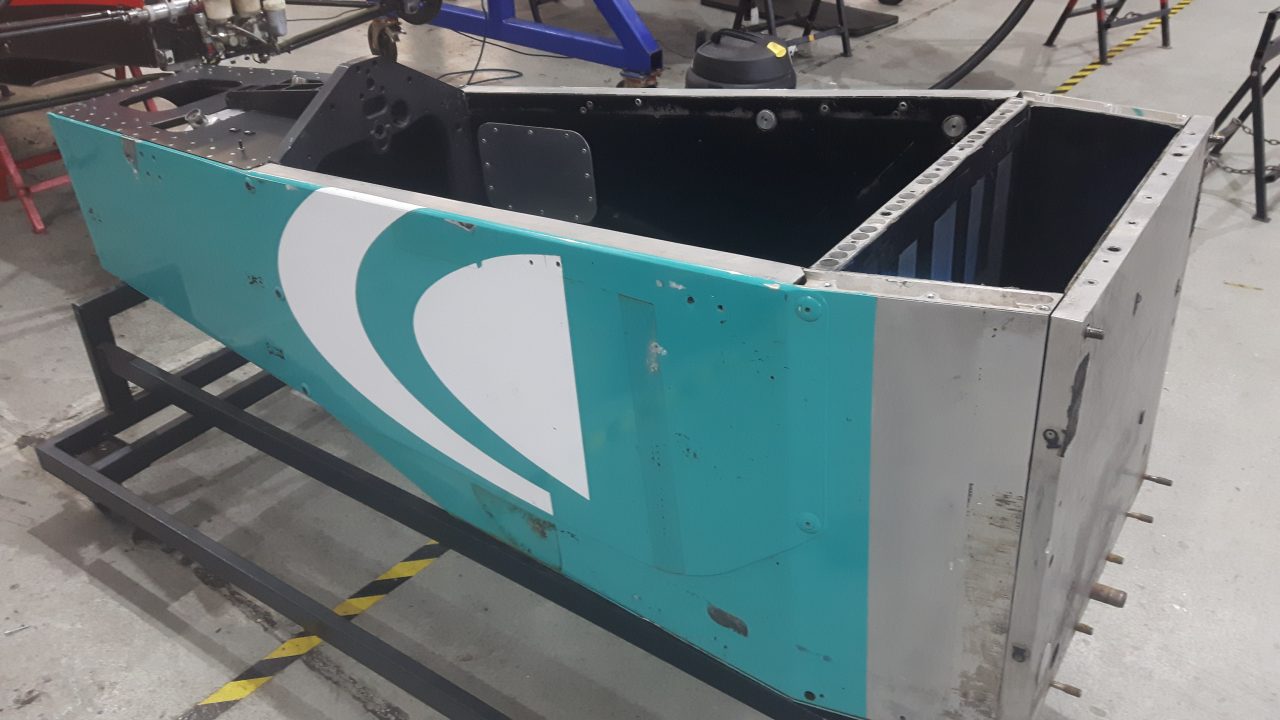

Customer was using existing single seated racing car for corporate motorsport events and needed the chassis engineered to be cheaper to manufacture and simpler to run and repair.

General spec included:

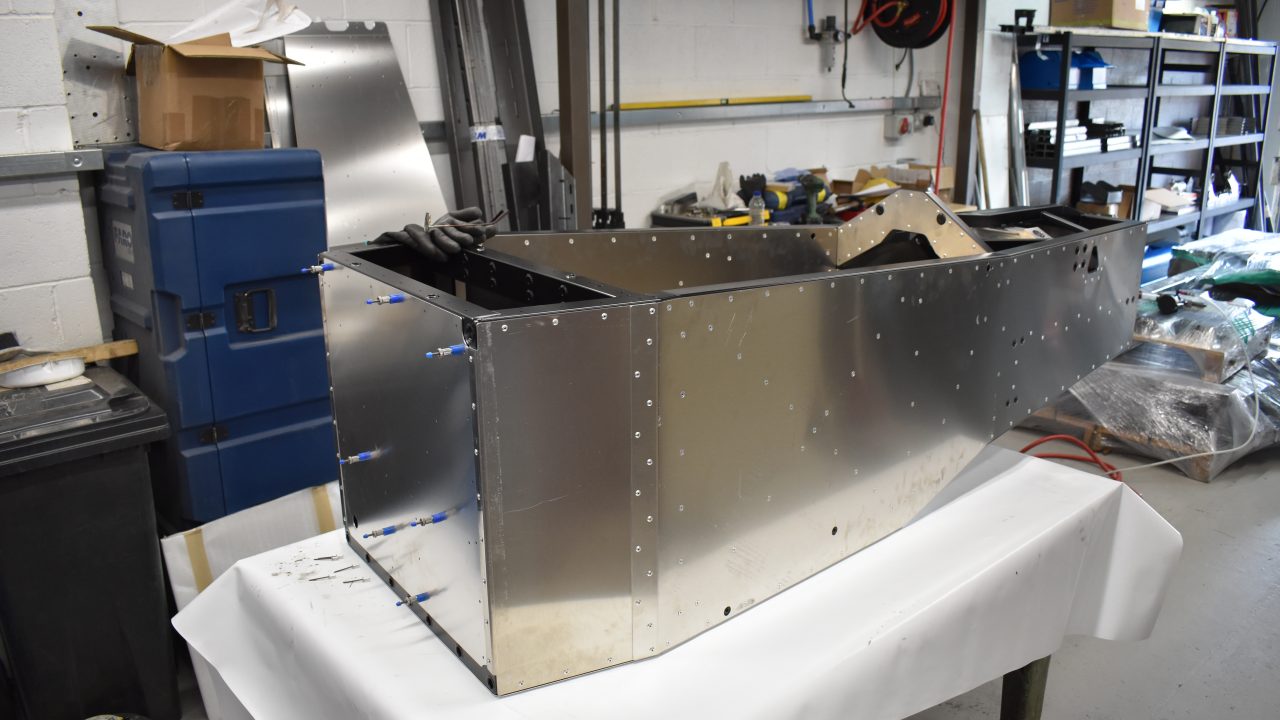

- Chassis had to accept all current running gear and bodywork

- Chassis had to follow the current internal and external dimensions

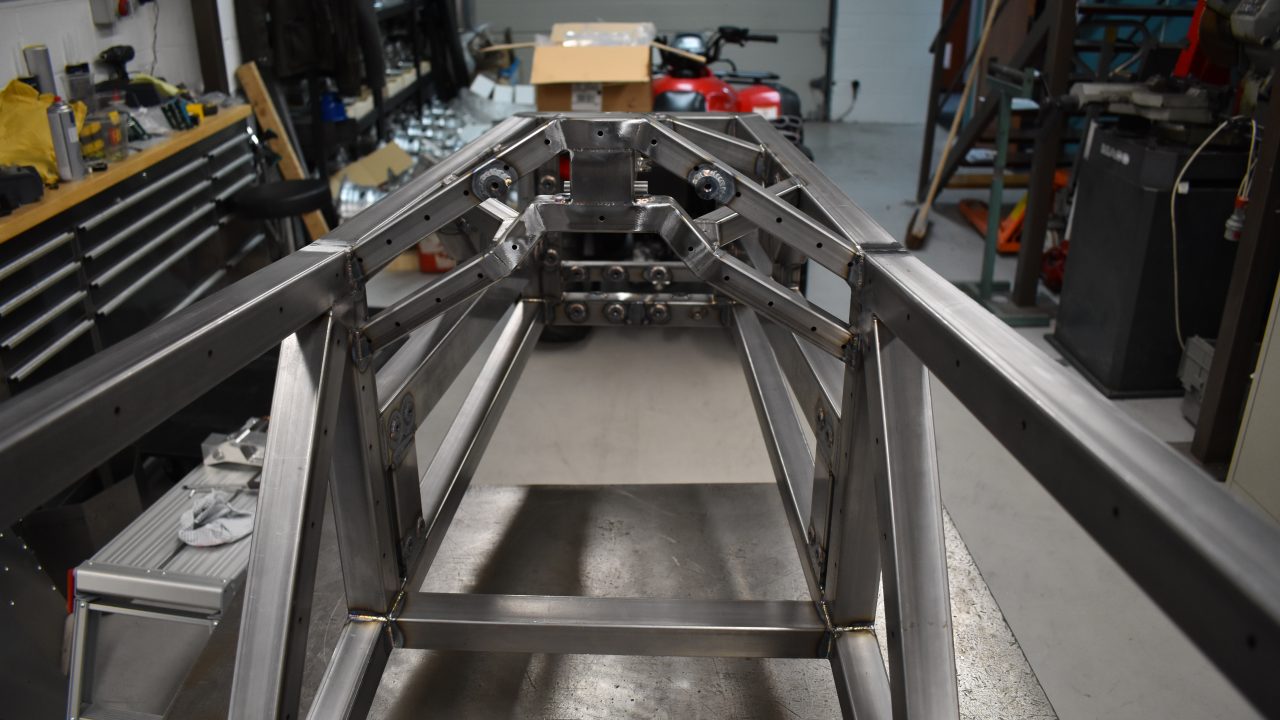

- A fully TIG welded steel box section tube chassis

- Project was full design and manufacture of 3 prototypes and manufacture of 10 production chassis

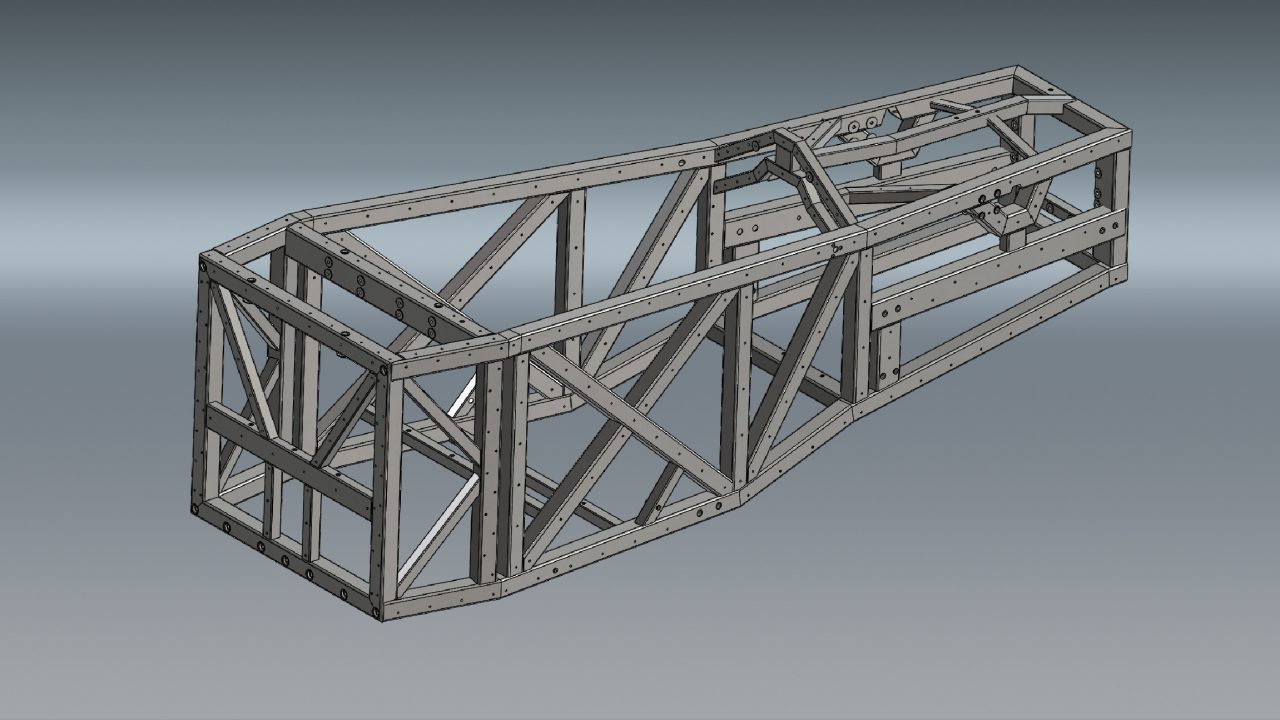

Design process

Process

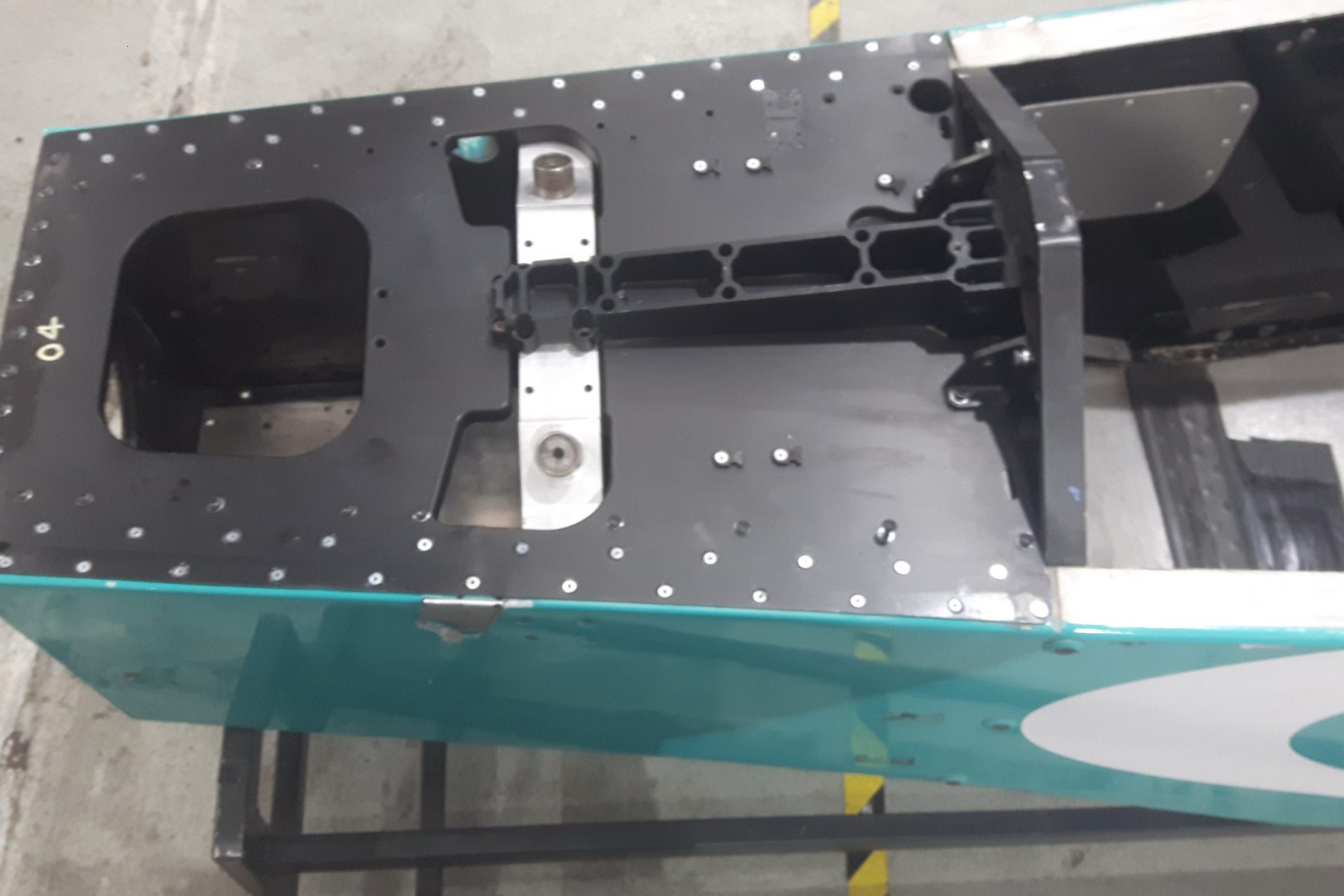

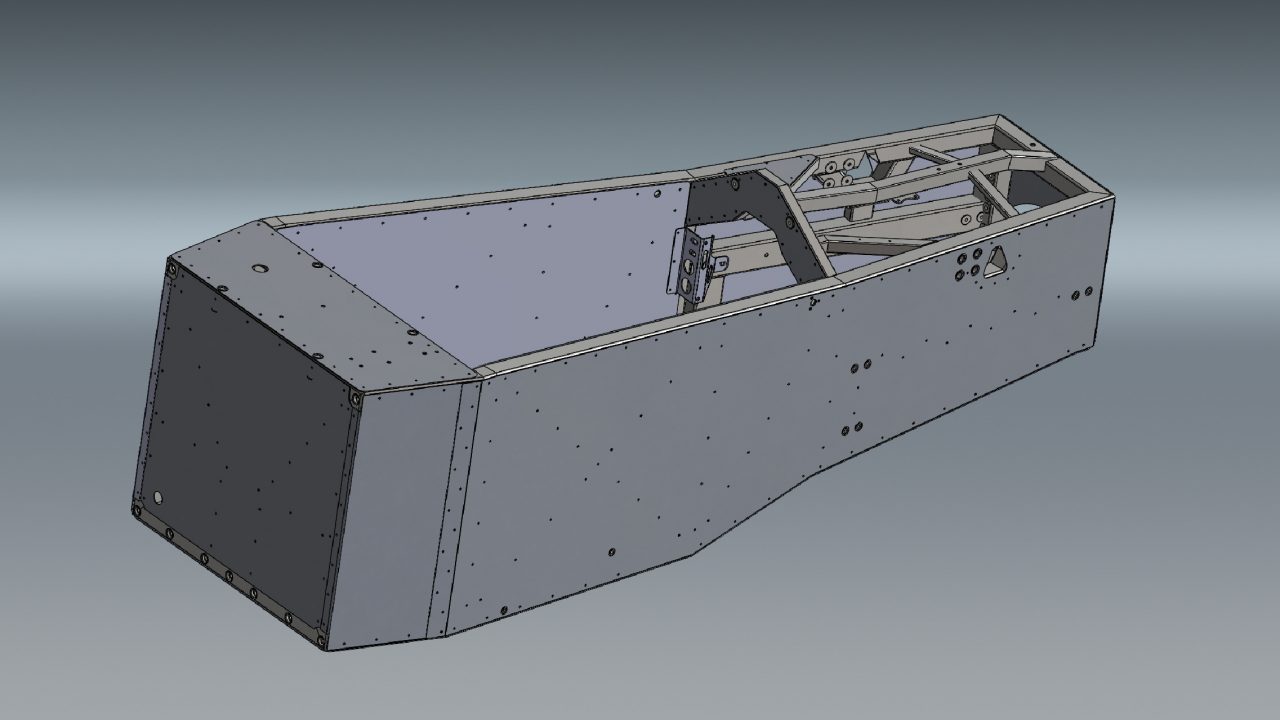

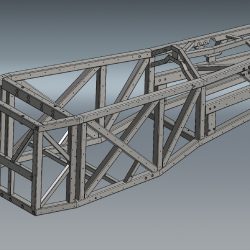

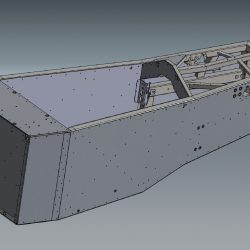

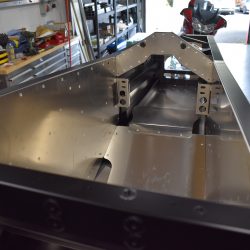

UV Design & Engineering designed a steel box section tubing spaceframe chassis using Solidworks 3D CAD to utilise innovative manufacturing processes:

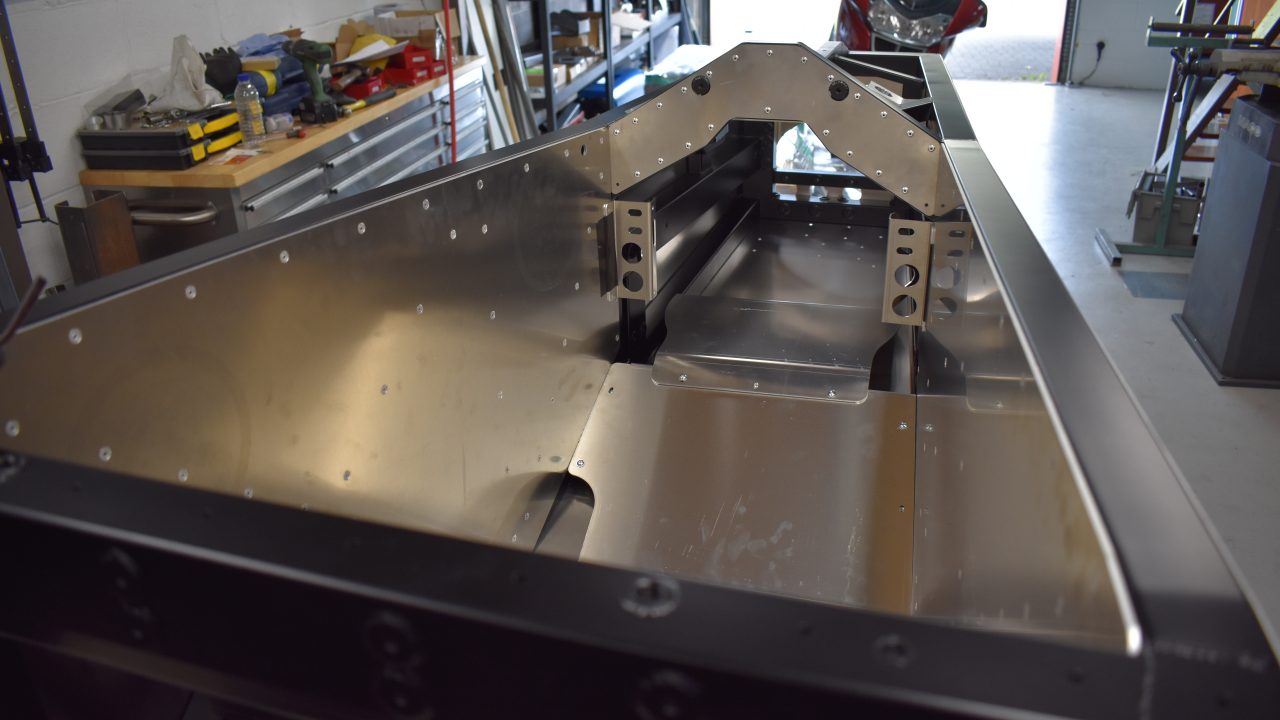

- All tubes were laser cut including rivet holes for the panels

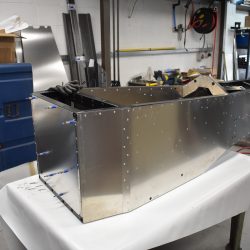

- All sheet parts were laser cut and folded by the supplier including the rivet holes

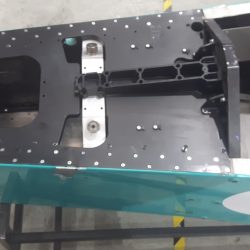

Chassis assembly process

Process

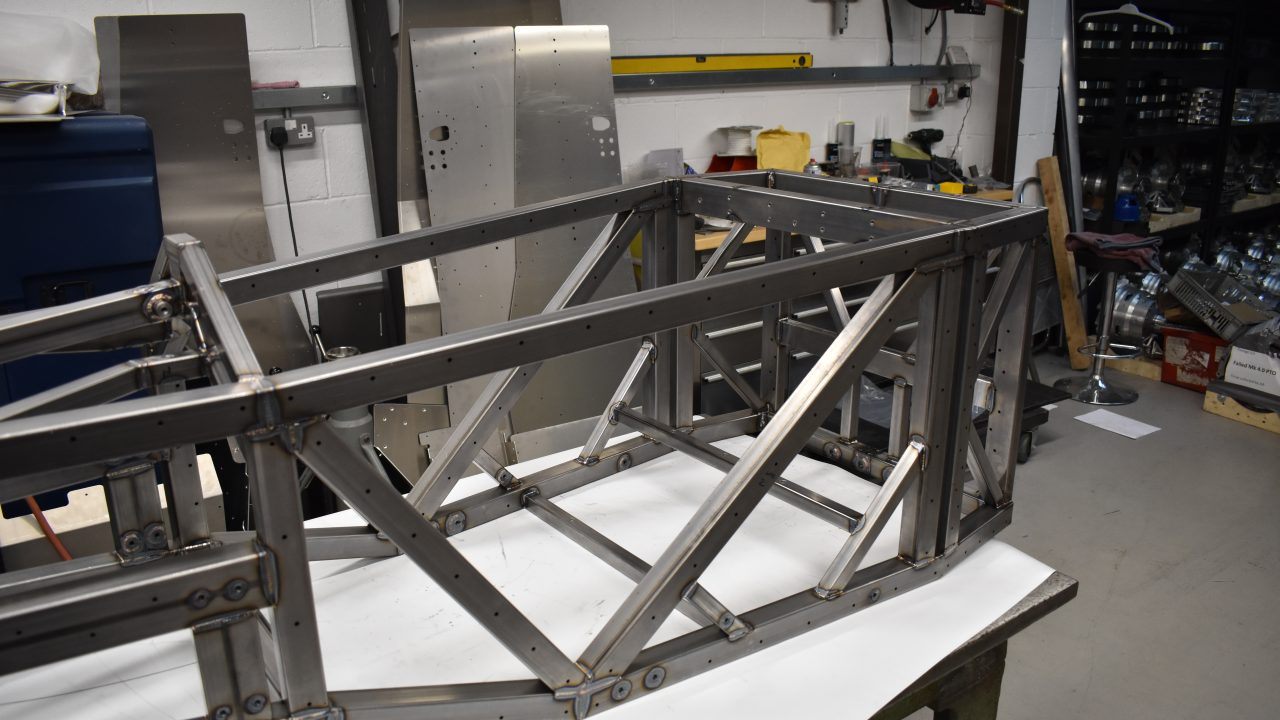

- Chassis tubes assemble using pegs or slots

- Minimal jigs and fixtures

- Body fixing holes in chassis tubes all pre cut and used with the panels for additional jigging purposes

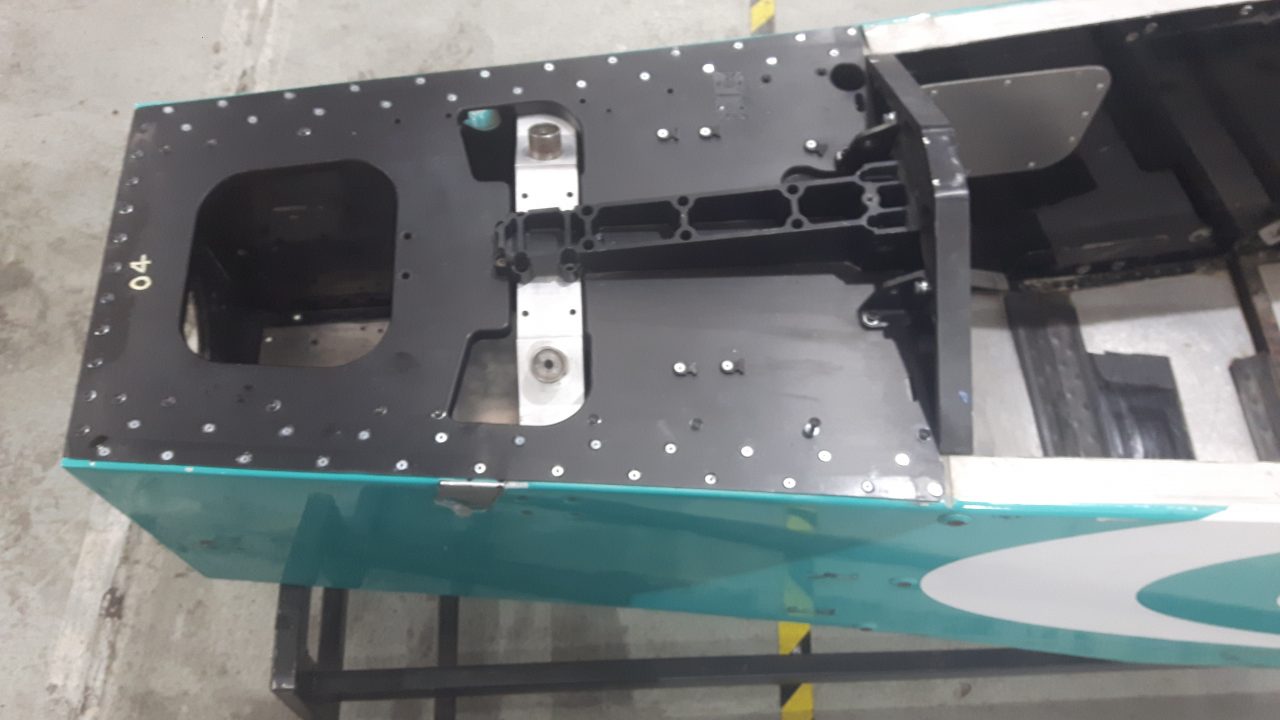

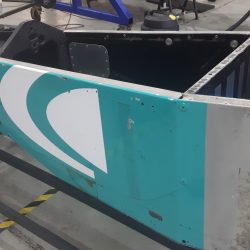

Chassis assembly and manufacture