Background

Customer required 3 buggies designed to resemble a vehicle from a movie. They required the buggy to be scaled down to suit being used in a small arenas

General spec included

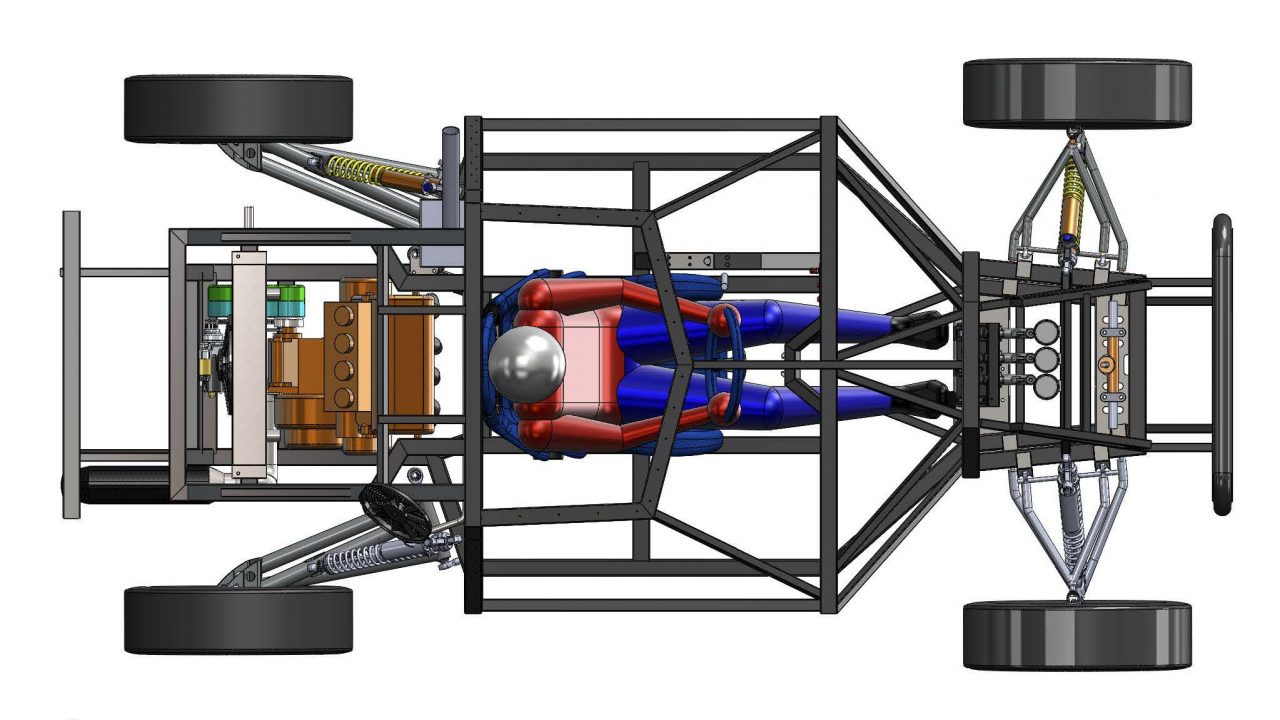

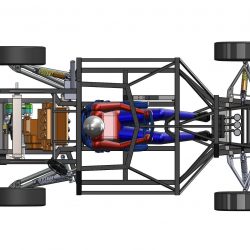

- Suzuki Hayabusa 1380cc engines

- Bespoke chassis design to suit body

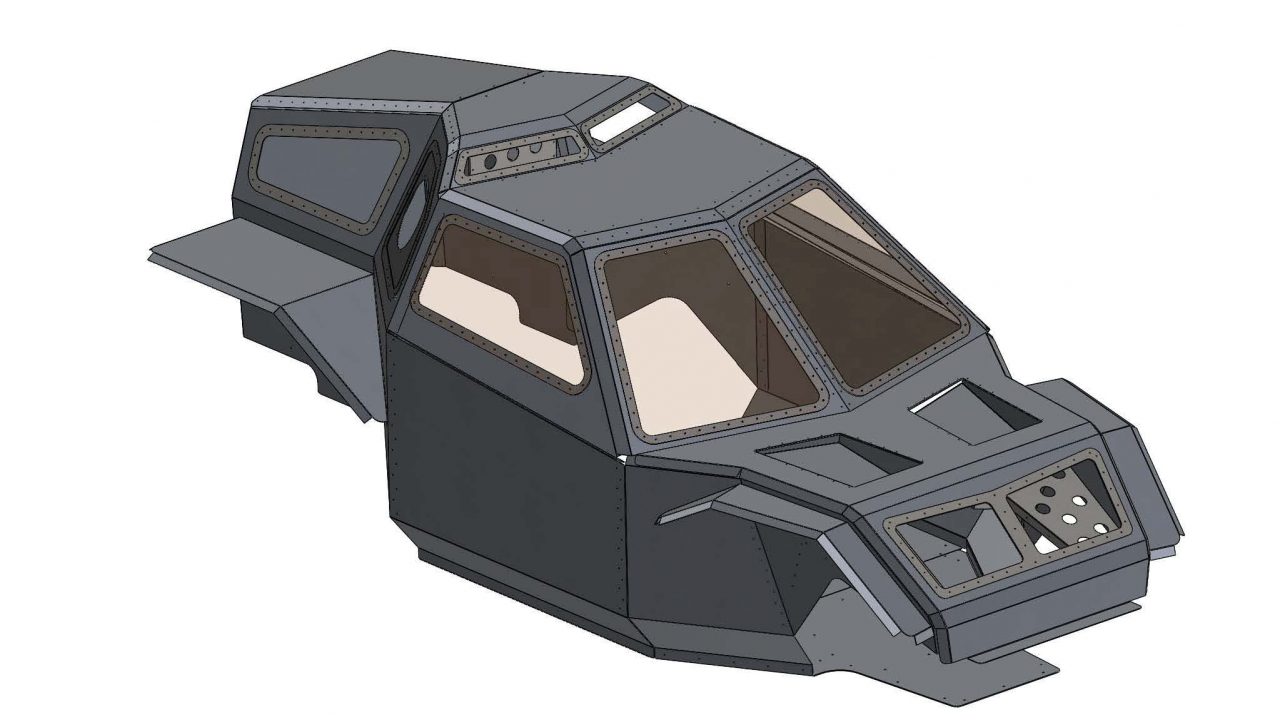

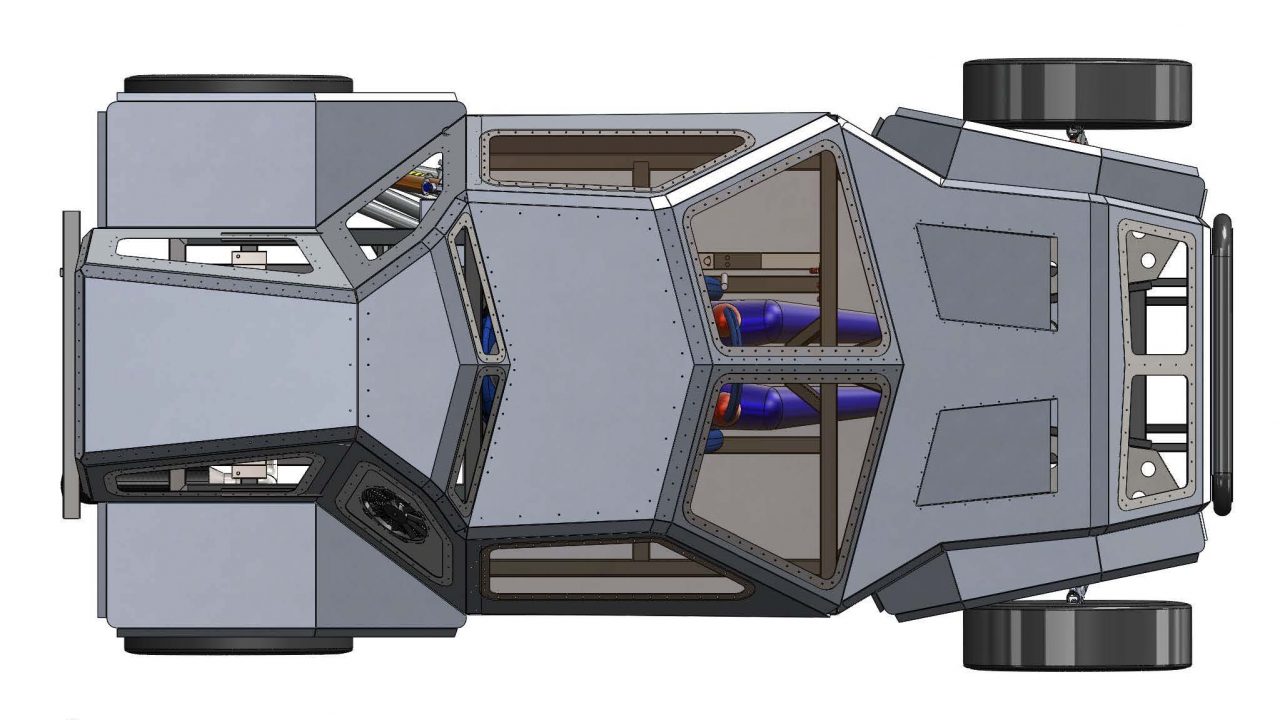

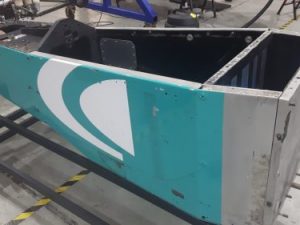

- Full aluminum panel body styled to resemble movie vehicle

- Project was full design, manufacture, build and test program to deliver running vehicles

- Bespoke gear drivetrain designed and manufactured for reliability

Design process

Process

UV Design & Engineering designed a body using aluminum sheet panels to resemble the movie vehicle, then designed a steel tube chassis to fit underneath incorporating of:

- Bespoke suspension components

- Bespoke gear drivetrain / spool differential

- Oversized radiator / cooling pack

- The supplier provided body panels ready to assemble and all rivet holes pre-cut

Chassis assembly & manufacture

Process

Once the design was completed and approved, all tube and sheet parts were laser cut to utilise innovative manufacturing techniques.

- All tube and sheet laser cut by sub-contract suppliers and supplied ready to assemble or weld.

- All tube and sheet parts assembled using pegs or slots – no jigs or fixture required.

- All parts assembled and fully TIG welded by UV Design & Engineering.

UV Design & Engineering manufactured all metalwork components in-house , including:

- All chassis parts

- All suspension components

- All water system parts

- All fuel system parts

Vehicles assembly

Process

UV Design and Engineering sourced and supplied all running gear components including:

- Suzuki Hyabusa engines

- Wiring harness

- Suspension

Project timescale

Process

- The project from start to completion took approximately 5 months

- We delivered the vehicles assembled, running and fully tested.

Video